1. Design requirements that meet medical standards

1. Oxygen purity and flow control

The core function of Oxygen Generator For Hospital is to provide high-purity oxygen to ensure that patients receive effective oxygen therapy. The oxygen purity provided by this product is 93%±3%, which meets the standards of medical-grade oxygen. This design takes into account the patient's need for high-purity oxygen, while ensuring that the equipment can maintain a stable oxygen concentration during long-term operation. In addition, the flow range of the equipment is 1-3L/min, and the adjustable flow design can adapt to the needs of different patients, ensuring the flexibility and reliability of oxygen supply.

2. Noise control

In a medical environment, noise control is particularly important because excessive noise may interfere with the patient's rest or treatment. The maximum noise level of Oxygen Generator For Hospital is 48dB. The relatively low noise design can effectively reduce interference with the hospital environment and provide patients with a relatively quiet treatment environment. The low-noise operation of the equipment also reflects the importance attached to the comfort of the medical environment.

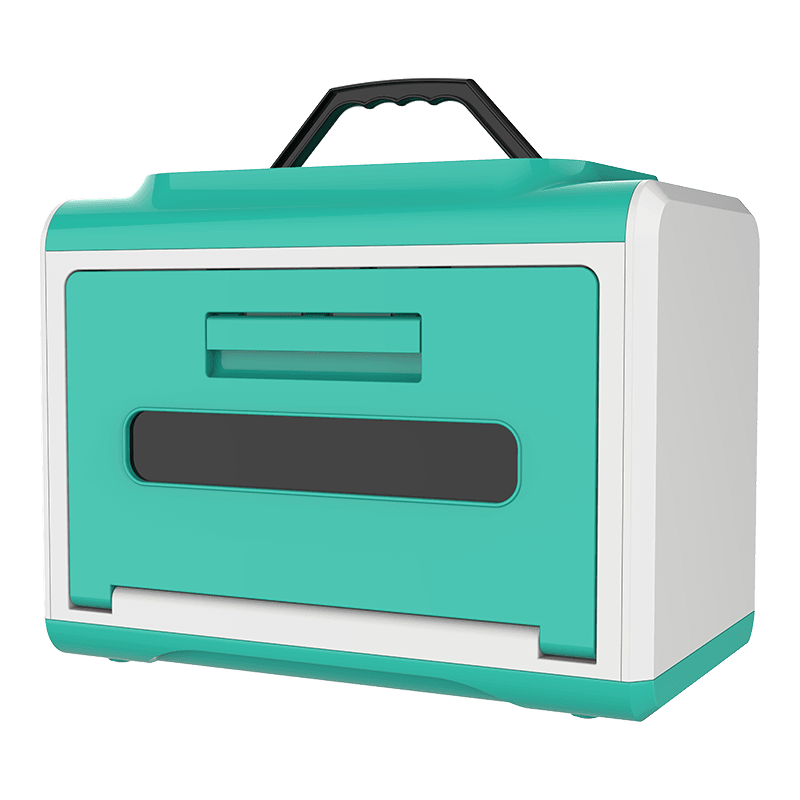

3. Dimensions and weight

The dimensions of the Oxygen Generator For Hospital are 337255475mm and the net weight is 12kg. The size design of the equipment takes into account the utilization needs of medical institutions for equipment space, and can provide efficient oxygen supply in a limited space. At the same time, the weight design of 12kg facilitates the movement and installation of the equipment, ensuring the flexibility of the equipment in different usage scenarios.

2. Durability and safety in medical environments

1. Material selection

The Oxygen Generator For Hospital is made of ABS material, which has good impact resistance, heat resistance and chemical corrosion resistance. The use of detergents and disinfectants is often involved in medical environments. ABS material has a strong tolerance to these chemicals, which can ensure the stability and durability of the equipment in long-term use.

2. Negative ion generation

The Oxygen Generator For Hospital is designed with a negative ion concentration of ≥8 million/cm³, which helps to improve the air quality in hospital environments. Negative ions can neutralize harmful particles and pollutants in the air, thereby improving the freshness of the air and having a positive effect on the patient's recovery environment.

3. Output pressure control

The output pressure range of the device is 0.03-0.05 MPa, which can provide a stable oxygen supply. The precise pressure control in the design not only ensures the stability of the oxygen flow, but also avoids the potential risks to patients caused by pressure fluctuations.

III. Easy maintenance and operation

1. User-friendly design

The design of Oxygen Generator For Hospital also focuses on the convenience of operation and the simplicity of maintenance. The device is equipped with an intuitive control panel, allowing medical staff to quickly set and adjust the oxygen flow and purity.

2. Convenience of maintenance

The design of the device also takes into account the convenience of maintenance. Since medical equipment requires regular cleaning and maintenance, the structural design of Oxygen Generator For Hospital makes it easier to clean and replace each component.

EN

EN

English

English 中文简体

中文简体

.png)